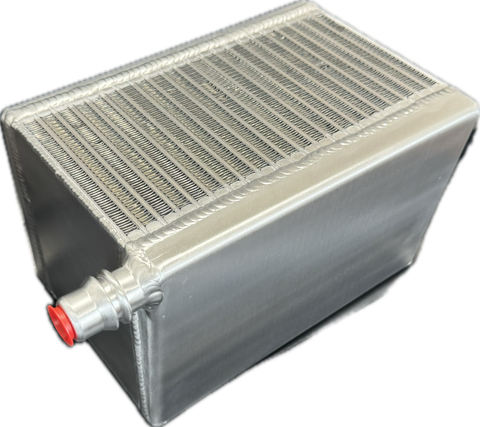

S58 Charge-Air Cooler Manifold V2

$6,499.99

$6,899.99

Product Overview

Transform your S58-powered BMW with our meticulously engineered billet aluminum intake manifold. Developed through extensive research and testing, this manifold represents the pinnacle of intake design, featuring advanced cooling technology and superior airflow optimization for unprecedented performance gains.

Key Benefits

- Superior airflow distribution

- 42.4% larger cooling volume vs OEM

- Advanced thermal management

- Cross-platform compatibility

- Premium 6061 billet construction

- Phenolic spacer included

Technical Advantages

- BELL AW600093050835 intercooler cores

- CFD-optimized flow pathways

- Enhanced plenum design

- Velocity stack runners (V2)

- Precision CNC manufacturing

- Thermal barrier coating

Engineering Features

- Advanced heat dissipation

- Reduced intake air temperatures

- Balanced cylinder feeding

- Optimized internal geometry

- Superior structural integrity

- Professional-grade construction

Performance Results

- Improved power delivery

- Enhanced cooling efficiency

- Better throttle response

- Reduced heat soak

- Consistent performance gains

- Superior thermal management

Installation Features

- Direct OEM replacement

- Complete mounting hardware

- Cross-platform fitment

- Professional documentation

- Comprehensive instructions

- No additional modifications required

| Feature |

OEM BMW Charge Air Cooler |

BELL AW600093050835 Charge Air-Cooler |

|---|---|---|

| Airside Fin Height | 5.75 mm | 5 mm |

| Waterside Fin Height | 2.75 mm | 1.84 mm |

| Air Rows | 27 | 22 |

| Water Rows | 28 | 23 |

| Core Size | 142 mm x 230 mm x 99 mm (3233.34cc) | 152.4 mm x 236.22 mm x 127 mm (4571.99cc) |

| Volume Difference | Base reference | +42.4% more volume |

Fitment

- 2020+ BMW G80 M3

- 2020+ BMW G82 M4

- 2020+ BMW G83 M4

- 2022+ BMW G87 M2

Professional installation recommended

Choose variants

Select title